New strategic collaboration announced to develop the fastest laser machine worldwide for fast production of bioinspired surfaces for consumer market

The European research project “LAMPAS” is working on the world record of fabrication throughput for the production of functionalized surfaces in the domestic appliance market by combining the outstanding characteristics of three laser technologies, being High-Average-Power Ultrafast Lasers, Direct Laser Interference Patterning and Polygon Scanner processing.

Technology developments related to high-power ultra-short pulsed lasers, advanced scanning techniques for new beam delivery concepts, together with interference patterning optics and real-time monitoring system have led to the collaboration of two technology giants to create a new system able to bring the functionalization of surfaces to the mass-manufacturing level. This collaboration is taken place in the framework of the European flagship project LAMpAS (research volume 5.1 Mio. €), launched at the first of 2019, with the goal to develop a new laser machine able to produce large-area and cost-effective micro- and nanostructures on various surfaces.

“The results envisioned in LAMpAS will make possible the production of a new generation of electrical appliance as well as food packaging systems, by adding new functionalities to the surfaces of daily used devices. We are very pleased to bring together the main industrial players for developing this new laser based system, for large-volume production. We are sure that the results will be groundbreaking for various industries”, announced coordinator Prof. Andrés Lasagni and could hardly hide his confidence about the success. He is fully aware of the forward-looking characteristics of the project.

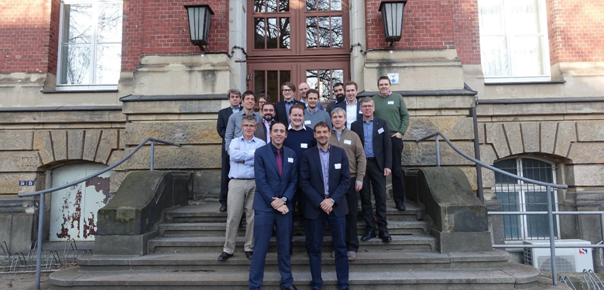

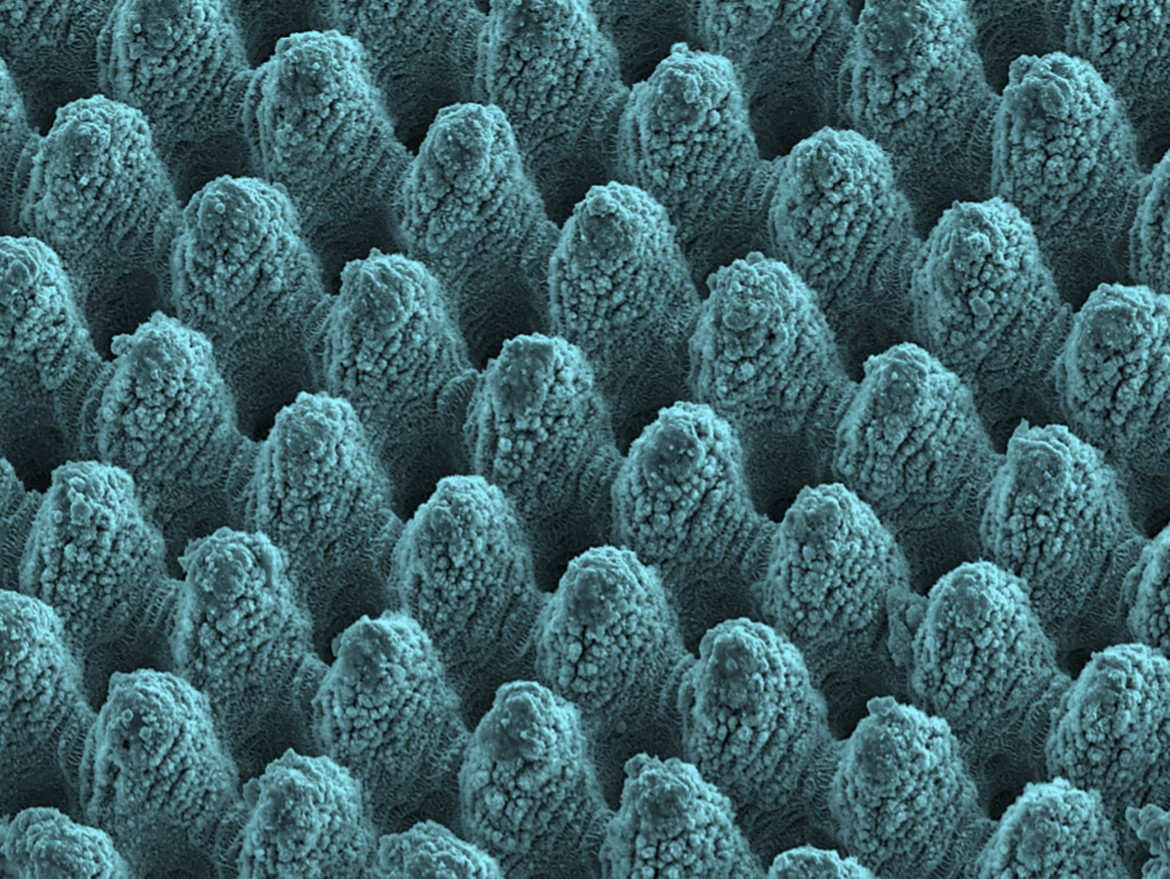

Antibacterial and self-cleaning properties, friction reduction, optical security functions and/or decorative effects on all kind of surfaces, the inspiration of such micro/nano surface structures is nature, as in the case of the lotus effect or butterfly wings. In this sense, technologies for modifying surfaces instead of composites or for coating surfaces can offer new industrial opportunities (e.g. long-term stable surfaces and more environmentally friendly processes).

Figure 1: Laser machined metal surface with self-cleaning properties. The distance between the individual structural elements (distance “peak” to “peak”) is approximately 10 micrometers. In comparison, a human hair has a diameter of 50-80 micrometers

The international research team includes scientists and engineers from TU Dresden, Bosch, Trumpf, Bosch-Siemens-Hausgeräte (BSH), Next Scan Technology, Near Infrared Technologies (NIT), Lasea und European Photonics Industry Consortium (EPIC).

Further information and current developments can be found on the homepage of the research association: www.lampas.eu.

Figure 2: Group photo of LAMPAS Kick off meeting in Dresden (22/01/2019)

The project is an initiative of the Photonics Public Private Partnership. www.photonics21.org (Grant Nr: 825132)

This document reflects only the author’s view and the EU is not responsible for any use that may be made of the information it contains.